"Throwing the baby out with the bathwater"

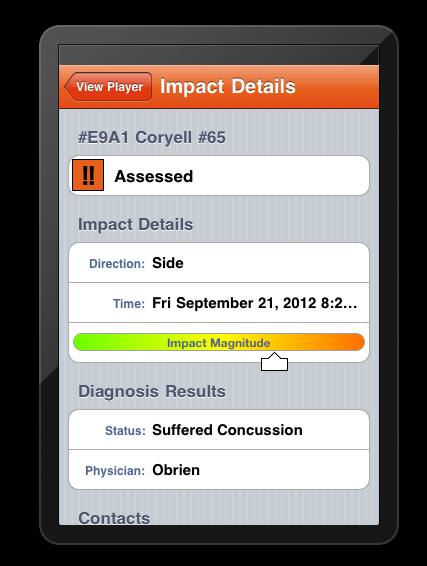

The heaviest criticism of the NOCSAE ruling has come from the manufacturers of helmet sensors, which monitor and measure the force of impacts to the brain during collision sports such as football and are designed to help identify possibly concussed athletes for sideline screening and evaluation, and is seen by many as a technological solution to the problem of chronic underreporting of concussions by athletes.

In a joint email to NOCSAE dated July 25, 2013, a copy of which was furnished to MomsTEAM, the CEOs of three helmet sensor manufacturers (Brain Sentry, Impakt Protective, and gForce Tracker) expressed a number of serious concerns about the NOCSAE position statement.

The CEOs acknowledged at the outset "the difficulty NOCSAE has in maintaining the integrity of its standards, given the development of many new after-market safety related products," which they viewed as the inevitable by-product of a "surge of creative and scientific energy and innovation now addressing the concussion crisis in contact sports," many proposing solutions which hold "significant promise."

While noting that NOCSAE was "uniquely situated, as a safety certification organization, to be a leader in identifying and eliminating potentially harmful products," the three companies expressed concern that, with its position statement, NOCSAE was "throwing away the baby with the bathwater."

"Inappropriate veto"

"The NOCSAE position statement gives helmet OEMs [Original Equipment Manufacturers] inappropriate veto rights over the certification of third-party sensor technology," they argued, and they questioned how NOCSAE compliance could be gained "without the potentially conflicted participation of the OEM helmet manufacturers," some of whom, as noted by Danny Crossman, CEO of Impakt Protective, Inc., the Canadian company that manufacturers the Shockbox helmet sensor, are testing or in the process of bringing helmet sensor systems of their own to market (such as Riddell, which is in the process of introducing its<"href="/node/6077"> InSite Impact Sensor System or may have them in the product development pipeline.

To avoid having to seek participation of the OEM helmet manufacturers in the NOCSAE certification process, the three CEOs proposed that:

- helmets with a third-party attachment be certified "where evidence of compliance with the NOCSAE standard can be demonstrated" with such attachment;

- helmet sensor manufacturers be allowed to "test at independent labs and obtain proof that their product does not affect the helmet impact absorption as per the NOCSAE standard"; and

- sensor manufacturers be allowed to provide NOCSAE "proof that any adhesives or attachment methods do not affect the material characteristics of the helmet shell."

Shockbox: Decision 'smells'

Reached in Texas, where he was attending a football coaches' convention, Crossman said that he not received a response as of yet from NOCSAE to the joint e-mail. "We have nagged NOCSAE," he said, but "it's like hitting against a wall."

Crossman criticized the NOCSAE statement as what he characterized as a "knee jerk reaction" to sensor technology that has been in the market for over two years. He viewed the ruling as being the "direct result of helmet manufacturer lobbying to protect their market" and feared that it would set back concussion research many years. "The release of the statement immediately prior to football season frankly smells," said Crossman. He called for NOCSAE to promulgate a new standard within the next 30 days to allow sensors to be tested on helmets at third-party labs without having to gain helmet manufacturer permission. "This is no different than a visor manufacturer testing a visor on a faceguard."

Crossman criticized the NOCSAE statement as what he characterized as a "knee jerk reaction" to sensor technology that has been in the market for over two years. He viewed the ruling as being the "direct result of helmet manufacturer lobbying to protect their market" and feared that it would set back concussion research many years. "The release of the statement immediately prior to football season frankly smells," said Crossman. He called for NOCSAE to promulgate a new standard within the next 30 days to allow sensors to be tested on helmets at third-party labs without having to gain helmet manufacturer permission. "This is no different than a visor manufacturer testing a visor on a faceguard."

"The position statement in itself is misleading and poorly drafted," said Crossman. "The statement about adding mass is erroneous since even mud, rain or grass adds mass, as do face-guards - which can weigh over half a pound, far more than the 1 ounce of mass added by the Shockbox sensor - which are applied after the helmet is tested. The issue of items affecting helmet reconditioning is a poor excuse since the helmets are vigorously sandblasted and stripped, cleaned and re-painted. If decals and stickers can be removed, so can the tiny Velcro strip that holds the Shockbox in place."

Crossman claimed that Shockbox has been tested in the labs at the helmet manufacturers as recently as April 2013 and shown not to affect the performance. "There have been over 45,000 impact tests with Shockbox in and on helmets by Impakt Protective in our test labs with over 500 youth athletes using Shockbox in clinical research trials. No helmets cracked, no-one was injured, no warranties were voided," Crossman noted.